Latex Foam Guide

If you are considering purchasing a latex mattress, you probably come across many new terms, such as 100% Natural latex, Organic latex, Blended latex, Synthetic latex, Talalay latex, Dunlop latex, and so on. This latex guide will help you understand the differences between latex types. In this guide, we will also cover the differences between Dunlop and Talalay Latex.

100% Natural, Organic, Blended, Synthetic Latex

For most of us, when we think of latex mattresses, we automatically think that all latex is natural and comes from the milk of the rubber tree. Unfortunately, this is not the case.

100% Natural Latex: As the name suggests, 100% Natural Latex is made with only natural latex. Natural latex is harvested as a raw liquid from rubber trees (Hevea brasiliensis). This liquid is then transformed into a latex foam without the addition of any synthetic latex. Rubber milk extraction is sustainable, and it does not harm the trees.

Organic Latex: Organic latex is similar to 100% Natural latex. 100% Natural latex is also considered to be Organic Latex. The difference comes from the farming methods used to grow the trees. 100% Natural Latex used traditional farming methods, while Organic latex is farmed with organic practices.

Blended Latex: Blended Latex is a combination of Synthetic Latex and Natural Latex. Blended Latex combines the durability of Synthetic Latex with the flexibility and elasticity of natural latex. Overall, blended latex is a great material for a long-lasting mattress. However, it isn’t the cleanest and most natural latex you can find for your mattress.

Synthetic Latex (We do not sell this product): Synthetic Latex is composed of 100% synthetic latex. It is a man-made version of natural latex. There is no natural latex included in the production of synthetic latex foam, keeping its production cost low. Synthetic latex is produced from petroleum compounds Styrene and Butadiene, which creates Styrene-Butadiene rubber known as SBR. As a result, synthetic latex has a similar formulation to other non-natural foams. Synthetic latex is also more durable because it lacks the elasticity element of natural latex. Because of its lack of elasticity, it feels stiffer than natural latex.

Talalay or Dunlop Latex: Which is best for me?

When choosing between a Talalay or Dunlop mattress, the most common question is which one is better? There is no simple answer. They are both great products, however, because they are produced differently, they present different characteristics.

Before we dig deeper into the differences, it is important to say that many people cannot tell much of a difference between the two; some cannot tell a difference at all, and some have a very specific preference. Thus, it will depend on how much your body can identify and feel the differences between the two, and which type your body will prefer.

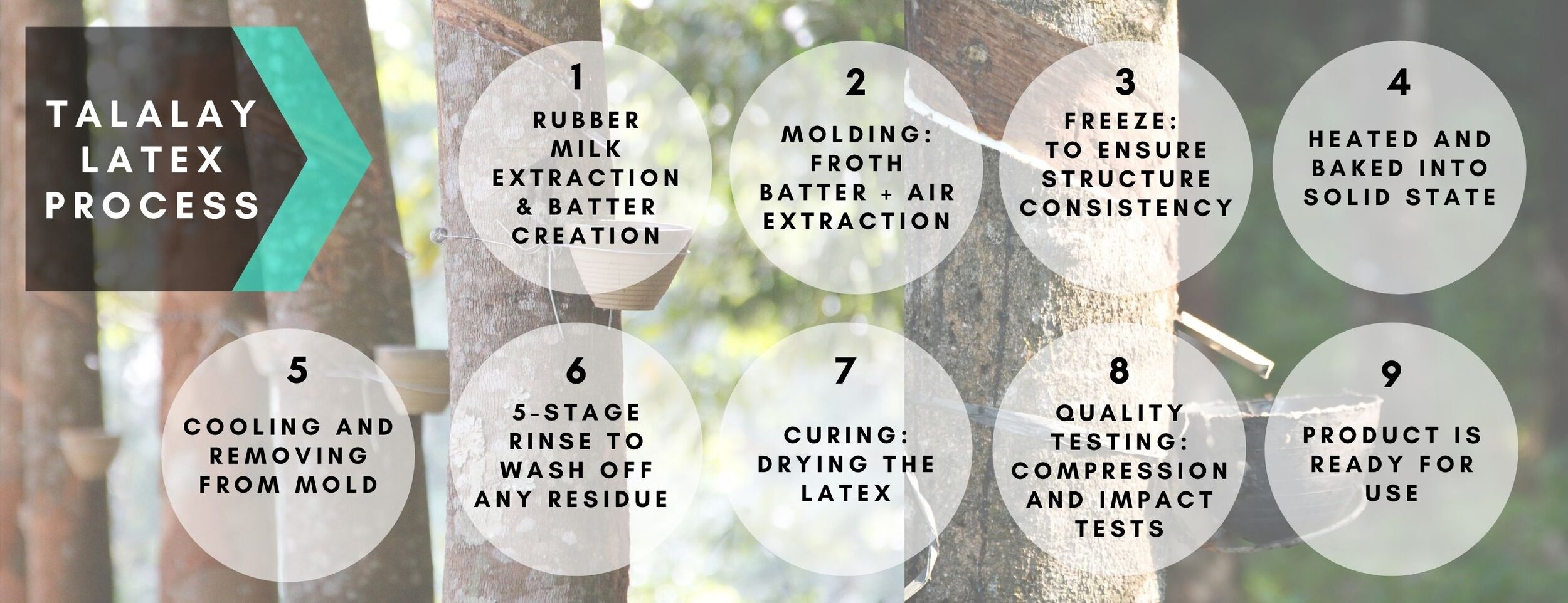

Talalay and Dunlop are two types of latex that result from different production processes. The Dunlop Process was developed in 1929 and was the first process used to create latex foam. The Dunlop process is simpler and faster than the Talalay Process. The Talalay process was developed by the Talalay family during World War II. The Talalay process is significantly more complex and costly but produces a more buoyant latex foam. Shown below we can see the Talalay Latex Process.

Step 1 - Harvesting: The rubber milk is extracted from the rubber tree.

Step 2 - Molding: The rubber milk is prepared into a batter to be transferred to the mold.

In the Dunlop Process, the batter is poured into the mold and gravity settles the particles that are naturally suspended in the liquid latex to the bottom of the layer. Because the batter is not whipped and the air is not infused into the batter, particles set on the bottom, creating a latex core that is softer on the top and firmer on the bottom.

In the Talalay Process, the batter is whipped to become a froth. This process infuses air into the batter. The batter is poured into the mold, and a vacuum is used to extract air and completely fill the mold cavity with foam. This part of the process ensures a consistent cell structure and increases the foam elasticity, which results in a more refined product with better pressure relieving.

Step 3 - Flash-frozen: This step is unique to the Talalay Process. The batter is frozen to a temperature of -20 degrees. Freezing prevents particles from settling, ensuring a consistent cell structure. The freezing process also increases the durability and longevity of Talalay Latex.

Step 4 - Flash-heated: The latex mold is heated to temperatures exceeding 220F to cure the recipe as it is baked into a solid state.

Step 5 - Cooling: Solid latex foam is cooled and removed from mold.

Step 6 - Five-Stage Rinse: This step is unique to the Talalay Process. Washing the solid latex ensures a cleaner latex, where any protein residue is washed away (which is a primary cause of latex allergies). Thus, for those that are allergic to latex, Talalay is a better option over Dunlop latex.

Step 7 - Curing: The solid latex is transferred to a dryer, where any residual moisture is removed.

Step 8 - Quality Testing: Quality testing includes an impact test and consistency test.

Impact test: The impact test measures the Indentation Load Deflection (ILD), a measure of firmness. A nine-point firmness consistency test measures the firmness throughout the solid latex. The nine-point includes three points in the head portion, three points in the hip area, and three points in the feet area.

Compression test: It simulates the effect of body impressions on the latex after a person lies on the bed for extended periods of time.

Talalay VS Dunlop

Each production process creates different characteristics related to the durability and longevity, the cost, the core breathability, the firmness level, and the way each type of latex feels. Let’s talk about each one individually to make things clearer.

Durability and Longevity: Pure latex foam is the most durable material for mattresses. All-natural Talalay and Organic Dunlop are both of great quality and last on average 12-20 years. In general, non-latex mattresses last an average of 5-7 years. Talalay mattresses tend to last a little longer, due to the Talalay latex process. The Talalay process creates a round cell structure. As the latex is compressed, a round cell structure does not break itself down. The Dunlop process creates a snowflake cell structure. As you compress a snowflake cell structure, the material will break down slightly faster.

Durability and Longevity are also dependent on the firmness of the latex. Firmer latex contains a higher percentage of rubber, increasing the lifespan of the product. Softer latex contains a smaller percentage of rubber and more air, decreasing the lifespan of the product. Thus, the firmer the mattress is, the longer it will last.

Cost: Since the Dunlop process is simpler and faster to produce, it is also less expensive (generally). Talalay is a longer and more refined process, which demands longer hours for production, increasing its price. Dunlop Latex is produced on a larger scale around the world. There are only a few latex plants that make Talalay Latex, reducing the availability of the product, and increasing its price. However, because Dunlop is faster to manufacture and it does not pass through the 5-stage washing step, it requires less water, making Dunlop Latex a more Eco-friendly process.

Breathability and Temperature Regulation: Talalay latex tends to retain less body heat due in part to its processing method; the flash-freezing pushes carbon dioxide through the latex, resulting in a more breathable material.

Firmness Level: Although both Talalay and Dunlop are available in 5 density/firmness levels, the Organic Dunlop Latex firmest level is firmer than the Natural Talalay Latex firmest option. Thus, for those looking for a firm or very firm mattress, the Organic Dunlop Latex is the best option.

Talalay Versus Dunlop Texture Comparison

Differences in the Feel and Texture: In the Talalay process, the latex rubber is whipped until it becomes a froth. This process infuses air into the batter. Thus, when the cores are baked, the resulting foam feels airy and resembles an angel cake. Talalay latex has a buoyant feel that contours well to body shapes, relieving pressure points, without making the body feel trapped as happens with memory foam mattresses. Talalay latex makes you feel like you are floating in bed.

In the Dunlop process, the air is not infused into the batter. Thus, when baked, the resulting foam feels less airy and resembles a pound cake. Dunlop latex feels denser, and contours less to the body curves, making it ideal for those that do not like sinking into the mattress. Because of its denser feel, Dunlop latex feels less bouncy and more sturdy than Talalay latex.